Verification of designs through analysis studies.

The finite element method is used to facilitate the analysis, preparation of innovative and better products, and to minimize the prototyping time. Structural analysis enables static and dynamic analyses required in advanced engineering, ensuring the creation of minimum prototypes and the pre-resolution of potential design issues under load.

Advantages:

1.Digital Testing Method:

At its core, it is a digital testing method. Components can be virtually examined in a computer environment before physically producing them.

2.Facilitates Design Revisions:

Since potential issues are visualized in a computer environment, adjustments can be made to the design, paving the way for a seamless design revision process.

3.Visualizes Structural Behavior under Various Loading Conditions:

Structural behavior and failure can be well visualized under various loading conditions.

4.Insight into Critical Design Parameters:

Insightful information is obtained regarding critical design parameters (Weight, Power, Cost).

5.Faster and Cost-Effective Design Cycles:

Enables a faster and more cost-effective design cycle.

6.Weight Reduction, Topology Optimization, Material Substitution:

Activities such as weight reduction, topology optimization, and material substitution studies can be performed more rapidly, effectively, and economically through the finite element method.

Regulation Analysis for Customer

According to OEM specifications, the following tasks need to be performed for OEM vehicle:

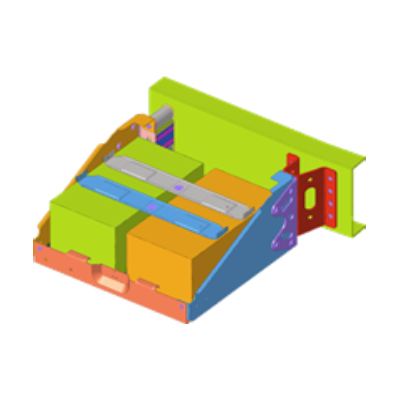

*Lightweighting studies on the mudguard carrier and battery carrier parts

*Bio-material studies on the screen carrier component

*Static and dynamic analysis modeling of components

*Correlation of analyses and tests

*Reporting design suggestions to the design team based on analysis results

*Conducting tests of completed analyses

*Project management, including regular meetings with customers and suppliers regarding analyses

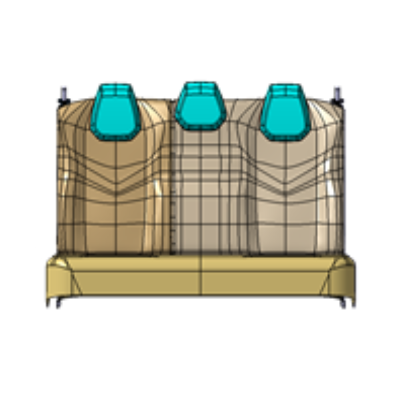

*Modeling of static and dynamic analyses for the bus seats of the Commercial Vehiclesaccording to ECE-R safety regulations and OEM specifications.

*Correlation of analyses and tests.

Reporting design suggestions to the design team based on analysis results.

*Conducting tests of completed analyses.

*Project management, including organizing regular meetings with customers and suppliers regarding analyses.

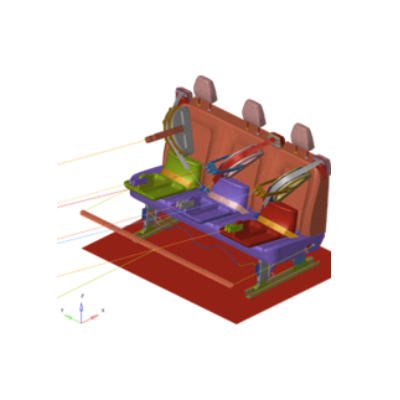

*Modeling of static and dynamic analyses for the center console and rear seat backrest of vehicles according to ECE-R safety regulations and OEM specifications within the scope of the R&D project.

*Reporting design suggestions to the design team based on analysis results.

*Project management, including organizing regular meetings with customers and suppliers regarding analyses.

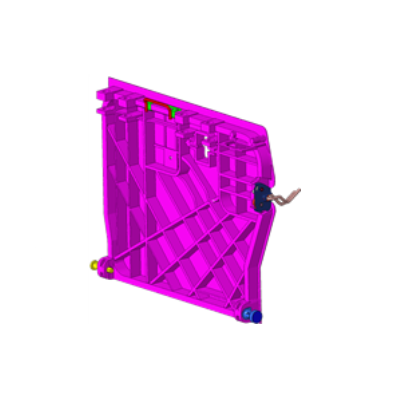

*Modeling of static and dynamic analyses for the rear passenger seat and composite trunk lid of vehicle according to ECE-R safety regulations and OEM specifications.

*Reporting design suggestions to the design team based on analysis results.

*Project management, including organizing regular meetings with customers and suppliers regarding analyses.